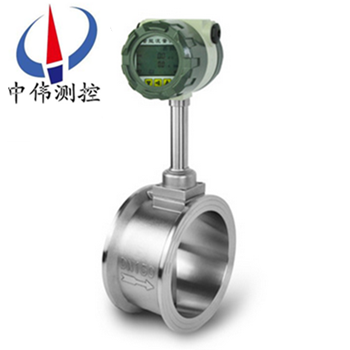

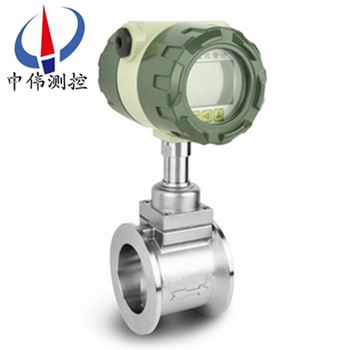

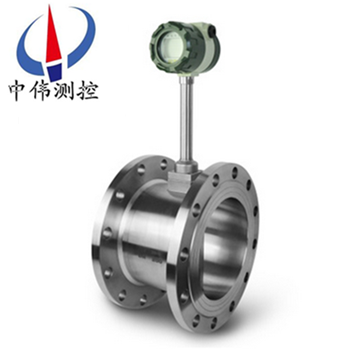

Vortex Flowmeter

I. Product Overview:

ZW-LUGB series vortex flowmeters are mainly used to measure the flow of medium fluids in industrial pipelines, such as gases, liquids, vapors and other media. Its characteristics are small pressure loss, wide range and high accuracy. It is almost independent of the parameters such as fluid density, pressure, temperature and viscosity when measuring volume flow rate under working conditions. No mechanical parts, so high reliability, small maintenance. Instrument parameters can be stable for a long time. The instrument adopts piezoelectric stress sensor, which has high reliability and can work in the range of - 20 ~250 ~C. It has analog standard signal and digital pulse signal output. It is easy to be used with computer and other digital systems. It is an advanced and ideal flowmeter.

From the above formula, it can be seen that the pulse frequency signal output by VSF is not affected by the changes of fluid physical properties and components, that is, the instrument coefficient is only related to the shape and size of the vortex generator and the pipeline within a certain range of Reynolds number. But as a flowmeter, mass flow should be detected in material balance and energy measurement. At this time, the output signal of flowmeter should monitor volume flow and fluid density simultaneously. Fluid physical properties and components have a direct impact on flow measurement.

ZW-LUGB series vortex flowmeter is a new type of flowmeter for measuring fluid flow in closed pipeline based on Carmen vortex principle. Because of its good medium adaptability, the volume flow of steam, air, gas, water and liquid can be measured directly without temperature and pressure compensation. The volume flow and mass flow of standard condition can be measured by temperature and pressure sensors. It is an ideal substitute for throttle flowmeter.

In order to improve the high temperature and vibration resistance of the vortex flowmeter, our company HLUG improved vortex flowmeter can be used under high temperature (350 C) and strong vibration (< 1g) bad conditions because of its unique structure and material selection.

In practical application, the large flow rate is much lower than the upper limit of the instrument. With the change of load, the small flow rate is often lower than the lower limit of the instrument. The instrument is not working in the working section. In order to solve this problem, it is usually used to reduce the diameter at the measuring place to increase the flow rate at the measuring place, and select the smaller caliber instrument to facilitate the measurement of the instrument, but this method of changing the caliber must be changed. There is a straight pipe section with a length of more than 15D between the caliper tube and the instrument for rectification, which makes the processing and installation inconvenient. The LGZ variable-diameter rectifier developed by our company has multiple functions of rectifying, increasing flow rate and changing flow velocity distribution. Its structure size is small, only 1/3 of the diameter of the process pipe. It is integrated with the vortex flowmeter. It not only does not need an additional straight pipe section, but also reduces the requirement for the straight pipe section of the process pipe. It is very convenient to install.

In order to use conveniently, the battery-powered local display eddy flowmeter uses micro-power high-tech, and the lithium battery-powered eddy flowmeter can run uninterruptedly for more than one year, which saves the purchase and installation cost of cables and display meters, and can display instantaneous flow and cumulative flow in situ. The temperature compensating integrated vortex flowmeter also has a temperature sensor, which can directly measure the temperature of saturated steam and calculate the pressure, thus showing the mass flow rate of saturated steam. Temperature and pressure compensating integrated sensor with temperature and pressure can be used to measure the gas flow directly, so as to show the standard volume flow of gas.

II. Working Principle:

ZW-LUGB series vortex flowmeter is composed of vortex generator, detection probe and corresponding electronic circuit designed in the flow field. When the fluid flows through the vortices, two alternating rows of vortices are formed on both sides of the vortices, which are called Carmen Vortex Street. Based on the theory of Carmen Vortex Street, the frequency of Carmen Vortex Street is proportional to the velocity of fluid, and the relationship between frequency and velocity is given.

F = St *V/d:

F Vortex Street Frequency (Hz)

Average velocity (m/s) on both sides of V-vortices

StStrohal coefficient (constant)

These alternating vortices form a series of alternating negative pressure, which acts on the detection probe and produces a series of alternating signals. After the pre-amplifier conversion, shaping and amplification, the pulse frequency signal (or standard signal) which is proportional to the synchronization of the vortices is output.

3. Use choice and application:

1. In order to use conveniently, the battery power supply type adopts the high-tech of micro-power consumption, and the lithium battery power supply can run uninterruptedly for more than one year, which saves the purchase and installation cost of cables and display instruments, and can display instantaneous flow and cumulative flow locally.

2. Temperature compensation integrative type also has temperature sensor, which can directly measure the temperature of saturated steam and calculate the pressure, thus showing the mass flow rate of saturated steam.

3. Temperature and pressure compensating integrated sensor with temperature and pressure can be used to measure the gas flow directly, so as to show the standard volume flow of gas.

4. It is widely used in process measurement and energy-saving management of low-viscosity liquid, gas, steam and other single-phase fluids in petroleum, chemical, metallurgy, machinery, paper-making, and urban pipeline heating, water supply, gas and other industries.

Fourth, main characteristics:

1. The flow of gas, liquid and steam can be accurately measured in a wide flow range without being affected by the physical properties of the fluid.

2. Not affected by temperature and pressure, and not easy to block, not easy to jam, not easy to scale, high temperature resistance, high pressure;

3. Safe explosion-proof, suitable for harsh environment;

4. No movable parts, no holes and seams