Mass flowmeter

I. product overview

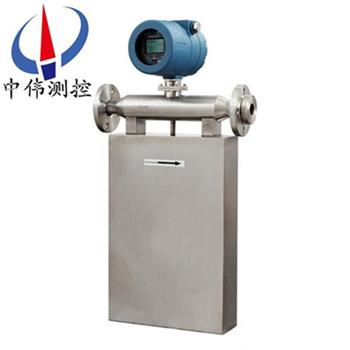

The zw-cmf series mass flowmeters can measure the mass flow rate, volume flow rate, temperature and density at the same time. There are integrated and separated structure design to meet different site installation needs. Balanced double measuring tube system can effectively reduce the interference of external installation stress and vibration. The high performance signal processing circuit based on microprocessor has higher measurement efficiency. No moving parts of the sensor, open flow detection design, to ensure the long-term service life of the flow meter.

Ii. Structure principle

1. Principle

The zw-cmf series mass flowmeters are designed with double elbow, and the measuring principle is to detect the mass flow in the pipe by measuring the mass flow in the double elbow. In the process of industrial production, sometimes it is necessary to measure the mass flow of the fluid, such as the material balance of chemical reaction, heat balance, ingredients, etc., all need to measure the mass flow of the fluid. Mass flow is the mass of a fluid flowing through a section of a closed pipe in a unit of time. The instruments used to measure mass flow are collectively called mass flowmeters.

2. Structure:

It is composed of sensor, transmitter and digital indicator accumulator. The sensor consists of sensing tube, electromagnetic driver and electromagnetic detector. The electromagnetic driver makes the sensor vibrate with its natural frequency, and the introduction of the flow rate makes the u-shaped sensor produce a kind of distortion under the action, in its left and right sides to produce a phase difference, the phase difference is proportional to the mass flow rate. The electromagnetic monitor converts the phase difference into the corresponding level signal and sends it to the transmitter. Convert to 4-20ma analog signals proportional to the mass and a range of frequency signals in two forms of output.

Iii. Application:

Zw-cmf series mass flowmeter is mainly used to measure the mass flow rate and the total volume, density, at the same time, it can also measure the volume flow rate and the total volume, medium temperature, moisture content, alcohol alcohol, mixed more uniform two liquid concentration, raw material ratio in the process flow. It is mainly applicable to the following industries:

1. Oil industry, such as crude oil output measurement, water cut measurement, single well output measurement and crude oil transportation measurement;

2. Chemical industry;

3. Food industry;

4, paper industry, such as pulp measurement;

5. Textile printing and dyeing industry;

6, energy transmission measurement, such as liquefied gas measurement;

7. Environmental protection industry, such as sewage treatment; The slurry density was measured during desulfurization.

Iv. Main features:

1. Directly measure the mass flow of the fluid in the pipe:

High measurement accuracy, good repeatability, can be in a large range, direct measurement of fluid mass flow; The measurement accuracy is high. The mass flow measurement accuracy of the flowmeter is 0.2 grade.

2. Stable and reliable work:

There are no obstacles and moving parts inside the fluid measuring tube, so it has high reliability and long service life.

3. Suitable width of the fluid medium:

In addition to the general viscosity of the uniform fluid, but also measured high viscosity fluid (honey, oil slurry, etc.); It can measure not only the fluid parameters of a single solution, but also the multiphase flow. It does not affect the measurement accuracy whether the medium is laminar or turbulent.

4. Wide application environment:

It is widely used in petrochemical, chemical, metallurgy, pharmaceutical, papermaking, food, energy and environmental protection industries.

5. Various real-time online measurement and control functions:

In addition to mass flow, the density and temperature of the fluid can also be directly measured. Intelligent flow transmitter, can provide a variety of parameters display and control functions, is a set of multi-function as one of the flow measurement and control instrument;

6. Good scalability:

The company can specially design and manufacture quality flow meters with special specifications, models and functions according to the needs of customers. Also can carry on the remote monitoring operation and so on.

V. technical parameters:

1. Measurement accuracy: [0.2% + (zero stability/instantaneous mass flow 100%);

2. Measuring repeatability: (1/2) [0.2% + (zero stability/instantaneous mass flow 100%);

3. Density measurement range: 0.2g /cm3 ~ 3.5g/cm3;

4. Density measurement accuracy: 0.002g/cm3;

5, temperature measuring range: 60 ℃ ~ + 200 ℃;

6, temperature measurement accuracy: + / - 1 ℃;

7. Current output: 4mA ~ 20mA;

8. Frequency output: 0Hz ~ 10kHz;

9. Contact capacity of batch control relay: 24V/ 0.1a;

10. Contact form of batch control relay: normally open (user's instruction when ordering, can be changed to normally closed);

11, fluid temperature: - 40 ℃ ~ + 200 ℃;

: 12, working environment temperature 0 ℃ ~ + 40 ℃.

13. Working environment humidity: 90% RH, non-condensing;

14. Atmospheric pressure: 86kPa ~ 106kPa;

15. Power supply requirements of the transmitter: AC (220 10%) V or (50 5%) Hz of the intrinsically safe power supply voltage, and 24 10%) V of the composite power supply voltage;

Power: < 15W.

Vi. Main functions:

1. Measurement function

It can directly measure the instantaneous mass flow rate of the liquid medium, the total cumulative mass flow rate, the total volume flow rate, the total volume volume, the temperature, the density, the concentration of the two-component liquid and so on. Can display, output, store and remote transmission; Modify the flow meter parameters.

2. Current output

With current signal output function, the current output is 4mA ~ 20mA, which can meet the control requirements of industrial instruments.

3. Frequency output

With frequency signal output function, the frequency output is 0KHz ~ 10KHz, which can meet the control requirements of industrial instruments.

4. Batch control

Volume control relay contact capacity: 24V/ 0.1a, the contact form is normally open (when the user orders, can be changed to normally closed), this function can meet the flow volume control of industrial equipment.

5. Communication function

This product has the data communication function, may pass the RS-485 communication, completes the data communication with the computer, may realize the computer network control.

6. Safe and explosion-proof

The company's mass flowmeter has been double explosion certificate.

Vii. Fault handling:

Liquid mass flowmeter generally will not fail, failure does not matter, careful analysis of the causes can make the problem solved, such as the working condition has not changed, there is no air, is not just check back to use and so on, the following briefly introduce several kinds of fault and treatment:

1. Hardware failure:

If the error is too large, the display of the integrator is not bright or value-added, the display is blank, etc., the reasons are as follows:

A. Improper installation can directly lead to zero drift of the flow meter. For example, the mass flow meter is installed near the pump outlet, the support strength of the sensor is not enough, the connection flange is welded improperly to generate stress signal, and the cable is subjected to electromagnetic interference.

B. Connection problem

If the display is not bright, should check the integrator power line, if the fuse is burned, should confirm the input voltage and standard voltage nominal value, ac and dc form is consistent. If the integrator does not increase with the flow, you should check the connection of the integrator, if the integrator is equipped with a positive/reverse program, you should check the flow meter connection, because the flow meter connection is not correct, will make the integrator in the reverse flow does not increase.

C. Process medium change

If the measurement medium appears gas pinch, gasification or two-phase flow phenomenon, the transmitter will appear alarm display, serious, sensor stop working.

D. Transmitter failure.

E. Sensor failure.

F. Pipe purging problem.

2. Software problems:

For just finished checking the flow meter installed before use must pay attention to under the current conditions of zero calibration, must ensure that the meter is filled with medium after close the cut-off valve on both ends to zero calibration, there are many kinds of, specific methods, hand operator panel operations and use ProLink Ⅱ software.

A. Zero point calibration error;

B. Parameter setting error;

C. Pulse fluctuation of power supply;

D. I/O configuration is wrong (do pay attention to the range);

E. Operation error.

Viii. Installation requirements:

The mass flow meter is a high-precision measuring instrument. In order to ensure the accuracy of measurement, the following environmental requirements shall be ensured:

1. The sensor (primary table) and transmitter (secondary table) shall not be installed in the area with strong magnetic interference, otherwise it will affect the circuit signal, thus affecting the measurement accuracy;

2. There shall be no other vibration interference in the pipeline installed by the sensor (primary table);

3, for the need to be installed in the outdoor situation, pay attention to z high and z low ambient temperature, should consider the wind and rain protection measures, avoid wind and rain, in order to improve the working life of the flow meter;

4. The ampere type flow meter transmitter (secondary meter) should be installed in a safe area or an appropriate control room;

5. The sensor of the ampere type flow meter (primary meter) and the transmitter (secondary meter) are connected by a 10-core shielded cable;

Ix. Installation:

1. Installation of horizontal pipeline

With the main body facing down, measure the liquid, and the outlet must be more than 0.8 meters high;