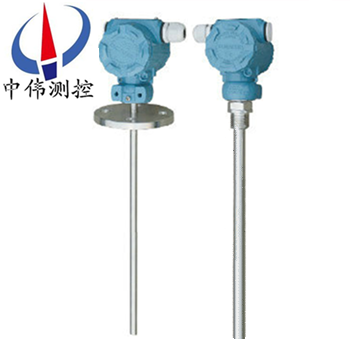

Guide rod type liquid level transmitter

Products overview:

ZW - DB504 seriesGuide rod type liquid level transmitterAdopts high performance ion silicon piezoresistive sensor, suitable for industrial process control field, the proliferation silicon technology integration of sensors have a combination of HART digital communication protocol design, can communicate with 475/375/275 hand operator, good stability, strong anti-interference and self-diagnosis capacity, replace the sensor does not affect the transmitter features, more convenient maintenance has the characteristics of small size light weight.Can also be used with the HART hand operator communication each other, through they are setting, monitoring, etc.

Second, the working principle:

ZW series - DB504 bar type liquid level with static pressure transmitter measuring principle;When the liquid level transmitter into the liquid to be tested in a certain depth, the sensor to meet the pressure on liquid surface formula is: Ρ = rho. We + Po type:

P: the pressure on the transmitter into liquid level

Rho: the measured liquid density

G: the local acceleration of gravity

Po: atmospheric pressure on the surface of liquid

H: transmitter into the depth of the liquid

At the same time, through the gas leading stainless steel will be introduced to the liquid pressure sensor of positive pressure cavity, and atmospheric pressure on the surface of the liquid Po and sensors connected to the negative pressure cavity, to offset the Po on the reverse of the sensor, the sensor measured pressure is: rho. We, obviously, through the acquisition of pressure P, can get the depth of the liquid level.

Applications:

ZW series - DB504 guide pressure bar type USES the import original component production pressure sensor, liquid level transmitter is mainly used in urban water supply and drainage, water treatment plants, reservoirs, rivers, oceans, oil tank, and oil level measurement, chemical, electricity and other departments.Instrument output two wire 4 ~ 20 madc standard current signal, with advanced technology, high precision, stable and reliable quality, convenient installation, detection is a kind of process control system in the ideal liquid level meter.

Four, the main features:

1, the use of unique guide technology, reasonable structure, reliable work.

2, prevent blocking structure design, can be used for viscous liquid and slurry.

3, wide application range and can be used for a variety of media such as crude oil, residual oil, wax oil, acid.

4, use temperature scope is big, can be used in high temperature.

5, can be convenient for temperature compensation.

6, installation, debugging and convenient.

7, simple structure, easy to maintenance.

Five, the technical parameters:

1, the detection range: 0.01 ~ 5 m;

2, fine degree: 0.2, 0.5;

3, pressure range: 0.1 MPa ~ 32 MPa;

4, agent and heat-resistant: - 50 ~ 250 ℃;

5, ground pole diameter: Φ 8;

6, the environment temperature: - 20 ~ 60 ℃;

7, storage temperature: 55 ℃ ~ + 125 ℃;

8, the output signal: 4 ~ 20 ma, 4 ~ 20 ma superposition HART communication, 485 communication, CAN bus communication;

9, the power supply voltage: 12 ~ 28 VDC (subject to security grid power supply);

10, fixed way: thread M20 x 1.5 installation, M27 x 2,

Flange installation DN25, DN40, (.Special specifications can be customized according to the requirement;

11, wet material: stainless steel, 316 1 gr18ni19ti or ptfe;

12, long-term stability: 0.2% FS/year or less;

13, temperature drift: 0.02% FS / ℃ or less (within 0 ~ 70 ℃);

14, explosion-proof grade: this Ann Exia Ⅱ C T6 flame-proof Exd Ⅱ C T5;

15, protection grade: IP67.

Six, measurement system:

Measurement system for this type.

This safety type pressure, differential pressure transmitter adopts the intrinsically safe circuit, suitable for explosion-proof grade ExiallCT4 - CT6 explosion danger area.

Shielding signal cable must be used in the system circuit, and reliable grounding.With only 4-20 ma output signal and the measurement system of 0 to 10 ma, for example the wiring diagram,

Liquid level transmitter has reliable operation, stable performance, small volume, light weight, low cost, refined design, a variety of structural form, easy installation, without stents.Circuit board USES the microprocessor based electronic technology, can automatically eliminate the influence of temperature change on the sensor precision.

This series of products can be equipped with LCD liquid crystal display (LCD), to facilitate the local operation.

Intelligent output with HART communication function at the same time.

Seven, the debugging methods:

Unscrewed the cap, you can see the zero and full range resistor, an external power supply and the current meter (0.2 or above), standard can be adjusted, the steps are as follows:

1, in the absence of liquid in the transmitter, adjust the zero resistor, make the output current of 4 ma;

2, add liquid to full scale in the transmitter, adjust full range resistor, make the output current of 20 ma;

3, the above steps two or three times repeatedly, until the signal is normal;

4, adjustment, tighten the protection cover.

Eight, to install:

1, the liquid level meter installed in the stillness of the deep well, sink, usually take around 45 mm diameter Φ steel pipe (different height to play several holes, so that the water flow into the tube) fixed in the water, then put type liquid level transmitter can be used in the steel pipe;

2, measuring flow, or have a mixing liquid level, usually take around 45 mm diameter Φ steel pipe (different heights on the opposite side of the liquid flow to play several holes, so that the water flow into the tube) fixed in the water, then put type liquid level transmitter can be used in the steel pipe;

3, the installation of the transmitter is in the vertical, the inputting type installation position should be far away from the liquid accesses and stirrer;

4, in the use of larger vibration occasions, can be on the transmitter winding wire, using steel wire suspension, so as to avoid tensile cables.

Nine, note:

1, due to the bottom of the tank or tank bottom easy deposition sludge, the content such as diesel, suggested leaving measuring probe tank (tank) at the end of a certain height, so as to avoid debris jam probe;

2, in the volatile medium, gas leading cable long, should be adopted to probe the sleeve should be fixed, in case the probe swings which might affect the accuracy of measurement;

3, when transmitter installation side, gas leading the bending radius should be more than 10 cm, to avoid excessive bending and will guide gas cable damage;

4, the inputting type liquid level transmitter earthing terminal shall be reliable grounding, power shielded wire should be connected with;

5, measuring, and explosive dangerous goods must be in strict accordance with the GB3836.1-83 "explosive environment with explosion-proof electrical equipment of general requirements and GB3836.4-83" intrinsically safe circuit and electric equipment "I", "the relevant provisions of the installation.

Ten, selection of details:

1, indicate the measuring range (level of), for some special medium, indicate the density of the medium.

2, type selection, attention should be paid to contact with the product of the measured medium material compatibility, for special medium, can be customized.

More than 3, the product installation in the thunderstorm area, the order should be marked "lightning", recommend that users install against lightning protection device at the scene, and make sure products and power grounding.

4, about the selection of gas leading cable length: general than the actual level of 1 ~ 2 meters long.

Eleven, selection of coding:

spectrum | instructions | ||||||||||

ZW-DB50 | In the liquid level transmitter (wei measurement and control) | ||||||||||

category | 1 | The cabling | |||||||||

2 | Lever (sensor installed at the bottom, direct contact with the liquid medium) | ||||||||||

3 | The anti-corrosion type | ||||||||||

4 | Guide pressure lever (sensors mounted on the upper, not direct contact with the medium) | ||||||||||

Process connection form | T | Bracket installation | |||||||||

N | Flange installationDN40 PN1.0 | ||||||||||

Y | Specifically agreed | ||||||||||

Sensor connection material | 1 | 304 | lever | ||||||||

2 | 316 | ||||||||||

3 | 316L | ||||||||||

4 | Nitrile butadiene rubber and PVC compounds | The cabling | |||||||||

5 | Ptfe, flange (pp) | ||||||||||

Explosion-proof way | O | Don't riot | |||||||||

E | Safety explosion-proofExia ⅡCT6 | ||||||||||

Display mode | O | Without the instructions | |||||||||

Z | With current meter instructions (0-100%Scale) | ||||||||||

X | A live show | ||||||||||

A counterweight | O | Without the weight | |||||||||

W | Need to weight | ||||||||||

-□ | The installation height (mm) | ||||||||||

-□ | Measure the height (mm) | ||||||||||

-□ | Density (measured mediumg/cm3) | ||||||||||

Twelve, design selection and ordering information:

1, model specifications: ZW - DB500 series;

2, the name of the measured medium, medium density;

3, instrument measuring range: can also be referred to as the nominal length;

4, work pressure, work under pressure;

5, working temperature: measuring the temperature of the liquid;

6, material requirements: liquid material;

7, whether matching supply flange, bolts, nuts, valves, fittings, such as sealing washer;

8, flange standard: nominal size of the flange, 3/4 ", DN25, (, DN80, DN100, etc;

9, special requirements: before ordering, please indicate in detail.

After-sales service commitment:

1, our company sold by liquid level transmitter series products within twelve months appear quality problem, is responsible for free maintenance.

2, the warranty period, any quality problems such as the products of our company, my company is responsible for free repair or replacement.

3, the warranty period, such as user improper use, damaged products, my company is responsible for the maintenance, charge damage parts cost.

4, after the warranty period appear quality problem, my company is responsible for the maintenance, charge damage parts cost.

5, such as user need to my company site services, to users in the province I company service personnel to reach the site within 12 hours, fujian association of foreign languages and user reach the site within 48 hours.