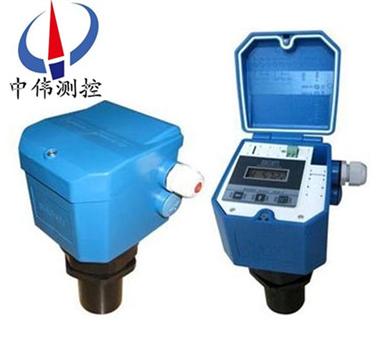

Ultrasonic level meter

Products overview:

ZWS - 200 k seriesUltrasonic level meterLearned the advantages both at home and abroad a variety of material level meter, realize the fully digital, humanized design concept, with perfect material/liquid level measurement, data transmission and human-computer interaction function.Main chip imported industrial microcomputer, digital temperature compensation and super wide voltage input voltage regulator and other related dozens of pieces of application-specific integrated circuit.Is featured by strong anti-interference, and can be arbitrarily set the lower limit for the output node and online, with the scene, according to the optional analog and switch quantity output and RS485, convenient interface and related facilities.

Second, the working principle:

ZWS - 200 k series working principle of ultrasonic liquid level meter is made by transducer (probe) high frequency ultrasonic pulse reflected back surface of the measured medium, the echo of part were the same receivers, converted to electrical signals.Ultrasonic pulse with acoustic velocity spread, from launch to receive needed by the ultrasonic pulse interval and the transducer to the surface of the measured medium is proportional to the distance.The distance between S and the relationship between the sound velocity C and transmission time T can be expressed in formula: S = CxT / 2.

Due to the launch of the ultrasonic pulse width to a certain extent, makes the distance transducer close small section area of the reflected wave and transmitted wave overlapping, unable to identify, can't measure the distance value.This area is referred to as the measuring blind area.The size of the blind area is associated with the model of ultrasonic.

The adoption of advanced microprocessor and unique EchoDiscovery echo processing technology, can be applied to all kinds of complicated conditions.Transducer built-in temperature sensor, the measured values of temperature compensation can be realized.

Ultrasonic transducer adopts the ideal acoustic matching techniques of the transmitted power radiation, can more effectively improve the signal strength, so as to realize accurate measurement.

Applications:

ZWS - 200 k series ultrasonic level meter can be widely used in petroleum, mining, power plants, chemical plants, water treatment plants, sewage treatment station, agricultural water, environmental monitoring, food, brewing, beverage, additives, edible oils, dairy products), flood control, flood prevention, hydrologic monitoring, open channel, space location and many other industries.

Four, the main features:

1, is featured by strong anti-interference.Nodes can be arbitrary set upper and lower limits for the output and online, with the scene, according to the optional analog and switch quantity output and RS485, convenient interface and related facilities.

2, using polypropylene waterproof shell.Shell is small and very strong, it has excellent chemical resistance, for inorganic compounds, regardless of acid, alkali, salt solution, in addition to the strong oxidizing materials, almost all of its no damage, for almost all the solvent at room temperature are insoluble, general alkanes, hydrocarbons, alcohol, phenol, aldehyde, ketone, etc all can use.

3, light weight, no scaling, no pollution medium.

4, non-toxic.Can be used in the food industry equipment installation, maintenance is very convenient.

Five, the technical parameters:

11, range: 0 to 4 meters, 0 to 7 meters, 0 to 10 meters, 0 to 15 meters, 0 to 20 meters;

2, measuring medium: a liquid or solid;

3, blind area: adjustable, less than 35 cm;

4, the measuring accuracy: + / - 3 mm or 3 ‰, take its head (standard conditions);

5, load: 500 ohm;

6, work stress: three under atmospheric pressure;

7, environment temperature: - 20 - + 60 degrees;

8, analog output: standard of 4 ~ 20 ma;

9, digital output: RS - 485, Modbus protocol (can be set by PC remote field devices);

10, open shut quantity: 1-3 way switch output;

11, show: highlight character LCD liquid crystal display;

: 12, the power supply voltage of wire 2 or 4 wire AC220V/DC24V;

13, protection grade: IP67.

Six, the main index is introduced:

1, the range.Can measuring range, reflecting the sensitivity of the transducer.The greater the range, the higher the sensitivity.You can configure the 4, 6, 8, 10, 20, 30 m different range of transducer, etc.When ultrasonic attenuation, reflection interface is poor, in order to avoid ultrasonic probe the received ultrasonic signal is too weak, noise and unable to distinguish, need to increase the transmission power transducer.

2, blind spots.Is also called dead zone, ultrasonic measuring less than a certain distance.When ultrasonic launch ultrasonic pulse, not the echo of detection at the same time.Due to the launch of the ultrasonic pulse width has a certain amount of time, at the same time after launch ultrasonic sensors and residual vibration, can not detect during the echo, so a short distance from probe surface down to detection, this distance is called the blind area.The same range of products, the smaller the blind area, means that the design of the transducer, the better.

3, temperature.The normal range is - 10 to 60 degrees Celsius.Although piezoelectric ceramic limit working temperature is 150 degrees Celsius, but ultrasonic most materials in the manufacturing process can long-term work in more than 100 degrees Celsius temperature.

4, precision.Mainly affected by the temperature change is bigger, in order to ensure the accuracy of measurement, most of the ultrasound with temperature compensation function.In the gas composition changes will also affect the accuracy of ultrasound, such as some volatile liquid, volatile after lead to air composition change, change in the velocity of gas, cause measurement error.At atmospheric pressure, and is not affected by the external environment disturbance cases, most manufacturer can be controlled within 0.5% precision.

5, two wire system with three wire system.Two wire system of ultrasonic power supply (DC24v) and the signal output (DC4-20 ma) share a loop, namely using only two lines, deficiency is transmitted power slightly weak relatively.Three-wire system ultrasonic is actually four wire system, its power supply (DC24v) and the signal output (DC4-20 ma) loop separation, the use of two lines, when they were connected to negative side, usually use three lines, its advantage is transmitted power is larger.

Seven, the advantages and disadvantages are as follows:

Advantages:

1, compared with the laser ranging technology, has the advantages of simple and economic.

2, ultrasonic technology generally do not need the moving parts, so again on the installation and maintenance more convenient;

3, ultrasound can not only fixed point and continuous measurement, and can provide telemetry, or remote control signal;

4, ultrasound compared with radioactive level measuring technology, do not need protection.

Technical features:

1, has the strong launch force transducer, the surface from cleaning, using the update of the transducer structure and manufacturing process, improve the work performance of transducer;

2, the microprocessor program control, intelligent signal processing technology, which can realize a variety of typical working condition of software processing mode, make the material level meter can adapt to the working condition of solid, liquid, dust and other complex;

3, infrared remote control programming, simple and reliable operation, and with an LCD scene shows;

4, non-contact continuous measurement, reducing maintenance;

5, can be used to measure the material level, space and distance, can also be used for standard or special switch tank automatic level - volume conversion;

6, with backlit LCD display, can display according to standard engineering unit.

Disadvantages:

1, when the ultrasonic propagation medium density changes, the speed of sound, too, will shift, seriously affect the accuracy of measurement;

2, pressure is more sensitive to temperature, so the general need under atmospheric pressure measurement;

3, some of the material has strong absorption of ultrasonic, when choosing measuring method and measuring instrument, we must give full consideration to the specific circumstances and conditions of the liquid level measurement.

Eight, the choice of the form of connection:

1, two wire system: two wire ultrasonic its power supply (DC24V only) and the signal output (D - 20 ma) share a loop, using only two lines, as the standard form of transmitter.

2, three-wire system: three wire ultrasonic is actually four wire system, its power supply (DC24V only) and the signal output (D - 20 ma) circuit separation, the use of two lines, when they were connected to negative side, usually use three lines.Its advantage is transmitted power is larger.

Three and four wire system: power supply (DC24V or AC220V) and signal output loop separation (D - 20 ma), use two lines, its advantage is transmitted power is larger, at the same time provides the high and low relay output, increased the new function.

4, measuring range:

A, according to the actual range to choose corresponding models of ultrasound.

B, if measured volatile liquid, please select a large range level model.

C, solid of effective range of the measurement of liquid level range of 1/2 to 2/3.

5, power supply form:

DC24V power supply:

A, give two wire series power supply current capacity shall be not less than 30 ma.

B, to provide three wire series power supply current capacity should not be less than 60 ma.

C, offers four wire series power supply current capacity shall be not less than 80 ma.

AC220V power supply:

Can only choose four wire series products, power supply current capacity shall be not less than 50 ma.

Nine, container installation conditions:

1, airtight container:

A, to 8 m below range, vessel to have more than DN65 flange, length without requirement of the flange to take over.

B, to 10 m, 12 m range, vessel to have more than DN80 flange, the flange of the over length is less than 150 mm.

C, to 15 m range, vessel to have more than 6 flange, the flange of the over length is less than 150 mm.

D, to 20 m, 30 m and 40 m range, vessel to have more than DN200 flange, the flange of the over length is less than 200 mm.

2, open container:

A, to 8 m below the range, the container should have a diameter of 65 mm above the installation.

B, to 10 m, 12 m range, the container should have a diameter of 80 mm or more installation, installation of mouth thickness is less than 150 mm.

C, to 15 m range, the container should have a diameter of 150 mm above the installation, installation of mouth thickness is less than 150 mm.

D, to 20 m, 30 m and 40 m range, the container should have a diameter of 200 mm above the installation, the installation mouth thickness is less than 200 mm.