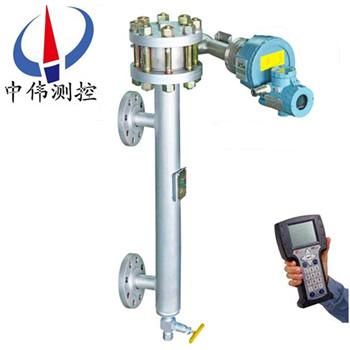

Intelligent electric buoy level (world) transmitter

Products overview:

ZW - TDZ/B seriesIntelligent electric buoy level (world) transmitterCore components of electronic components and sensors are FOX of the United States imported, the product that maintain the original properties of the transducer, and optimize the product structure upgrade, improve the cooling performance of transmitter, comprehensively promotes the use of the transmitter reliability.Transmitter according to its different functions, can be divided into two kinds of standard and intelligent.Models are: 1, the standard electric float transfeeder models: ZW - TDB;Model: 2, intelligent electric buoy transfeeder ZW - TDZ.

1, TDB ZW - series standard electric buoy type liquid level transmitter, USES the advanced weighing sensor technology, make the measurement system has high measurement precision, stable performance, strong ability to resist overload eccentric characteristics.Transmitter to the change in the liquid level interface or the proportion of continuous converted into 4 ~ 20 ma. Standard DC current signal output.At the same time, the meter pointer in the form of percentage of continuous indicates that the value of the measured parameters.Output signal remote transmission to the control room, realize the remote display of the measured parameters or control of the process.

2, ZW - TDZ series intelligent electric buoy type liquid level transmitter, to adopt advanced technology of weighing sensor, the sensor and the main components selects the import high quality components, transmitter using microprocessor technology, 4 ~ 20 ma output analog signals and superimposed on the signal in accordance with the HART communication protocol of the digital signal.Therefore, intelligent transmitter has a line on the output characteristics, monitoring, remote configuration, remote diagnosis and adjustment functions.Intelligent transmitter should be equipped with a hand held programmer, the whole Chinese portable PC - HART com, etc., can be used with all conform to the HART protocol devices connected to the Internet, digital detection and two-way communication and process control.

Second, the working principle:

ZW - TDZ/B series intelligent electric float liquid level (world) transmitter capacity is measured by the float chamber (top mounted), buoy, torque tube system and electronic measurement system, etc.Buoy submerged in liquid measure, let indoor, rigid connection and torque tube system, the torque tube system under the weight of force is a buoy minus the buoy the net value of buoyancy, in under the action of the resultant force torque tube torsion Angle.

Buoy, let indoor location, density of liquid, or changes the position of submerged in liquid, the buoyancy of the buoy is change so that twisted tube Angle changed also.The change is passed to the torque tube on the rigid connection of the sensor, the sensor output voltage changes, and then be amplified electronic components and converted into 4 ~ 20 ma output current.Transmitter USES microcontroller and related electronic circuit measuring process variables, provide current output, drive LCD display and provide the HART communication ability.Electronic components within the transmitter can not only to the environment temperature compensation and linearized processing ability, at the same time because of the process change caused by the temperature of the liquid density changes in the corresponding compensation.

Applications:

ZW - TDZ/B series intelligent electric float liquid level (world) transmitter can be widely used in petroleum, chemical, refining, pharmaceutical and other industries of various container liquid level, layered interface or the proportion of continuous measurement.

Four, the main features:

Use the hand held programmer and other equipment to the HART communication protocol on site and remote intelligent transmitter does the following:

1, read the process variables such as the original value, mA, percentage range, etc.;

2, zero and range set by hand operator adjustment or use the transducer zero and full potentiometer;

3, read the diagnostic information information are: parameter is set too high, too low;Range of measurement;4 ~ 20 ma beyond range, etc.;

4, HART communication instruction using hand operator or other equipment and intelligent transmitter to communicate, can be read on screen information such as the PV value, current value and percentage.Can use all HART instructions within the scope of implementation.

Five, the technical parameters:

1, the measuring accuracy: + / - 0.5%;Plus or minus 1.0%;Plus or minus 1.5% (FS);

2, acuity: 0.05%;

3, the output signal: standard: 4 ~ 20 ma. DC, two wire;24 v DC power supply intelligent: 4 ~ 20 ma, superposition in conformity with the HART protocol digital signal;

4, load resistance: rated 250 Ω, zui 600 Ω, high load resistance with the power supply voltage;

5, outlet: M20 x 1.5 (in);

6, work stress: 1.6 ~ 16.0 MPa;

7, medium temperature: - 20 ~ 150 ℃, 150 ~ 400 ℃ (heat sink);

8, medium density: 0.4 ~ 2.0 g/cm (level measurement), dense degree of poor: acuity 0.15 g/cm (measurement interface);

9, explosion-proof type explosive-proof grade: ExdIICT4-6, ExiaIICT4 -, explosionproof qualification card number: 8060710, shell protection grade: IP66;

10, environmental conditions: temperature, and 20 ~ 60 ℃, humidity, 85% or less;

11, connection mode: flange connection, DN40, flange standard: PN1.6, 2.5, plane, JB/T81-94, PN4.0 ~ 16.0, convex, JB/T82.2-94, also can be made according to standard provided by the user specifications and;

12, material qualitative, floating cylinder: 1 cr18ni9ti, float chamber and the flange: 1 cr18ni9ti Q235A or;

Six, debugging:

1, the transmitter before delivery have been conducted according to the order by debugging, but after long-distance transportation turbulence or long-term inventory, installation or equipment overhaul before use, need to check the main properties of the transducer.

2, sign "medium density (bad)" column indicate the scope of, refers to the measurable station transmitter density in any liquid in this range.

3, sign "factory debugging density (bad)" column in the annotation data, refers to the data provided by the user, and according to the density (poor) to debug the factory.In actual use, if the density of the measured medium (poor) change, should according to the actual density (poor) to debug.

Seven, debugging equipment required:

1, adjustable power supply: 0 ~ 30 v DC.

2, milliammeter: 0 ~ 30 ma. DC, plus or minus 0.2%;

3, load resistance: 250 Ω, 1 only;

4, second-class standard weight: 1 kg, 1 set;

5, scale: 1 only;

Eight, debug method points to hang heavy method and water standard method of two kinds:

Hung heavy method:

Liquid level debugging:

1, the buoyancy calculation:

L buoy buoyancy: F1 = PI / 4 d. h. rho

L buoy heavy G and the difference between the buoyancy: F2 = G - F1

Type: D - buoy diameter (cm);

H - buoy length range (transmitter) (cm)

Rho - medium density (g/cm3)

2, fix level transmitter on the calibration on the shelf.

1) zero debugging ma (4)

On the tray into the buoy with heavy G such as heavy weight (including pallet), zero adjustment potentiometer, make the output of 4 ma.

(2) full debugging 20 ma)

With F2 in tray into the equivalent amount of weight (including pallet), adjusting range potentiometer, make the output of 20 ma.

According to (1), (2) two step, adjust a few times repeatedly, until satisfied.

3 interface debugging:

Calculated separately on the basis of the two kinds of medium density weight density of buoyancy FQ and Fz

FQ = PI / 4, D2, h. rho Q

FZ = PI / 4 d. h. rho z

Type: D - (cm) H - buoy long buoy diameter (range) (cm)

Rho Q - light medium density (g/cm) rho z - heavy medium density (g/cm)

4, according to the FQ and FZ calculate the zero hung heavy weight weight fo hang heavy weight weight FM and full scale.

fo=G-FQ

fm=G-FZ

Type: G - weight buoy marked (sign)

1) zero debugging ma (4)

L on the tray into the same fo farmar (including pallet), equivalent to the value of the zero potentiometer, transfer to 4 ma

If l rho Q light medium density is higher than when placing order, provide the density of 0.1 g/cm3, it is possible tuning out 4 ma phenomenon.At this point, according to zero potentiometer will adjust the direction of the original 10 turns in the opposite direction, make the potentiometer is basic in the middle position, to adjust the density of the potentiometer, make the output of 4 ma.Then zero adjustment potentiometer, make the output of 4 ma accurate values.

2) full debugging

On the tray in the FM equivalent weight, adjustable range potentiometer, make the output of 20 ma.

Water proof method:

1. The liquid level debugging

Medium density of 1 g/cm3 or less (water) : according to the density and the measured medium range, calculate the full scale of the water level height h (mm) : h = h. rho

Type of H - buoy the length (span) mm:

Rho - measured medium density, g/cm3

2, zero debugging:

Net buoy indoor water, zero adjustment potentiometer, make the output of 4 ma.

3, full debugging:

Open the inlet valve, added water to the buoy indoor, make higher water equal to h, immediately shut off the water valve, adjusting range potentiometer, make the output of 20 ma.

According to (1), (2) two step, adjust a few times repeatedly, until satisfied.

4, medium density > 1 g/cm3 (water) :

When the density is greater than the density of water measured medium, will take any point within the range as a full pilot (cap) is set.Debugging before, should first calculate the corresponding water level and point by point within the range of the current value.

For example: the range of 1500 mm, the medium to be measured density is 1.1 g/cm3, take 1300 mm for full (limit) the pilot, is:

Corresponding water level should be: h = 1300 * 1.1 = 1430 (mm)

Which corresponds to the current should be followed: Ⅰ = 4 x 16 + 1300/1500 = 17.87 (mA)

After the calculation, debug method is as follows:

1, zero debugging

Net buoy indoor water, zero adjustment potentiometer, transfer to 4 ma.:

2, full debugging

Full debugging is at level 1430 mm for the range potentiometer, make the output of 17.87 mA, repeated several times, until satisfied.

3, interface debugging

Two kinds of medium density 1 g/cm3 or less (water)

L, according to two different kinds of medium density respectively calculate the zero level corresponding h0 stated (mm) and full of water level height h (mm)

H0 rho Q = H

Hm = H rho z

Type of H - range (buoy long mm)

Rho Q - light medium density (g/cm)

Rho z - heavy medium density (g/cm)

After l calculated h0 and hm, the scale line with buoy underside height as a benchmark, draw the h0 and hm, respectively, on the scale of markup

4, zero debugging:

L to buoy indoor infuse water, the water level is equal to the h0, close the inlet valve, zero adjustment potentiometer, make the output of 4 ma

If l rho Q is higher than the density of light medium when placing order, provided by the density of 0.1 g/cm or more, it may be transferred out 4 ma phenomenon.At this point, the zero adjustment potentiometer in the direction of around 10 turns in the opposite direction, the potentiometer is basic in the middle position, and adjust the density of the potentiometer, the output is 4 ma, then again zero adjustment potentiometer, make the output of 4 ma accurate value, 2) full debugging

To buoy the indoor infuse water, making water level equal to hm, close the inlet valve, adjustable range potentiometer, make the output of 20 ma.

According to the above (1), (2) two step, adjust a few times repeatedly, until satisfied.

Heavy medium density > 1 g/cm3 (water)

Full adjustment, preferable than zero the debug level h0 any point as a full range of pilot, specific methods can refer to water level debugging "medium density > 1 g/cm3 (water)" debug method.

5, commissioning method of measuring the proportion of:

Debug method and measuring interface basic same, just calculate the buoyancy is poor, by the same proportion of medium in zui daiwa zui small to calculate the two points.

6, the linearity of the debug method:

Good linearity modulated before they go out in the transmitter, the user generally do not need to check, just according to the parameters set zero and full (upper and lower limit).If user want to check linearity, according to the following formula to calculate weight, check any point within the range of linearity.

1) when measuring liquid level

Farmar, any position (x %) = G - PI / 4 d, x %, h. rho

2) any position when measuring interface heavy weights (x %) = G - PI / 4 d. H (x % Δ rho + rho (Q)

3) when the proportion of measurement

Calculation formula and the liquid level measurement formula are basically the same, just according to the proportion of different weight value calculation.

All kinds of: G - buoy weight (G)

H - buoy length (cm)

Rho - medium density (g/cm)

Δ rho - two kinds of medium density difference, Δ rho = rho z - rho Q

Rho z - heavy medium density (g/cm)

Rho Q - light medium density (g/cm)

X % - the percentage of span length (buoy)

Nine, measuring interface zero migration issues:

Measuring interface, buoy the upper parts are immersed in the medium, therefore, will produce certain buoyancy, the buoyancy is a constant, additional current produced by it is also a science, it raises the good range without any influence, just lead to zero point slightly higher than the modulated good zero value (ma) 4, this additional current value is very small, if the measurement accuracy is not high, just don't have to zero migration, if the measuring accuracy is higher, need to attach the current migration.

Here are two kinds of migration methods, for reference:

1, will buoy indoor all full of light medium (note: must make the buoy upper parts all immersed in the light, medium, and adjust the zero potentiometer, make the output current 4 ma.

2, can be observed in any of the interface, the zero adjustment potentiometer, make the output current and the interface point corresponding to the current value.The above two kinds of debugging method, the user can choose according to actual condition, other methods may be adopted.But please note that no matter what method is adopted to improve the migration, can only be zero adjustment potentiometer.

Ten, use and the matters needing attention:

Installation note: 1, high temperature medium

For some high temperature medium application, must pay attention to limit environmental temperature within the scope of the permit.If used in high heat capacity of the enrichment medium (keep) 300 ℃ saturated steam, or holding with (about 300 ℃) with hot oil heating jacketed heat, direct effect on the sensor shell and electronic components of the environment temperature should not exceed 50 ℃.For example, the use condition of occasions to allow zui big limit temperature (sensor shell temperature 80 ℃, 65 ℃, electronic components LCD indicator 60 ℃) over, all components of the radiant heat (clamping body, the outer barrel, container, etc.) must be insulating, to make sure that no thermal radiation is passed on to the sensor and amplifier.

2, the position of the transmitter installation, should avoid direct sunlight sensor shell and electronic components.

3, the clamping body with hot jacket, jacket in the original design of zui big work pressure is 2.5 MPa.Specific cases (order)

4, instrument inside and outside the ground should be solid, reliable explosion-proof product installation shall be in strict accordance with the law of the People's Republic of China on the explosive dangerous location electrical safety regulations relevant provisions on a trial basis.The Ann system, laying cable should be far away from the interference sources, so as not to affect the normal operation and explosion-proof instrument performance.When applied to 0, must use the fire penetration of fasteners.