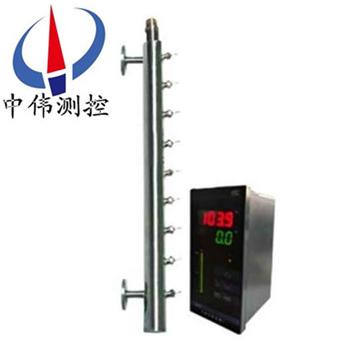

Double color electric contact water level gauge

Products overview:

ZW - UDZ seriesDouble color electric contact water level gaugeIndoor and outdoor can be applied, the rainy day can rain, and lightning protection.Under the bad environment corrosion and explosion proof;Resistance to high temperature and high pressure;Good sealing and leakage protection;Without the blind spots, direct display, wide measuring range, suitable for all kinds of tajikistan, cans, spherical vessel and boiler equipment such as medium level detection.Choose the alarm switch, which can realize level upper limit and lower limit alarm and control.Choose level remote transmission signal, the output: 4-20 ma, which can realize remote detection, record and control, direct can direct communication with PC or PLC system flow.

Second, the working principle:

ZW - UDZ series double color electric contact has a float level meter, float on the basis of the proportion of each medium in the manufacture, the movement of the float inside the magnet steel and the liquid level in the same height of the container, liquid level meter LED display of internal magnetic sensors are scale, each other to produce the electromagnetic induction and converted to the corresponding potential value, trigger the corresponding electric circuit, the liquid level above through the red LED display is clear, below the liquid level through the LED display clear green, red vapor phase, green display liquid, red and green light junction is the practical level of container.

Applications:

ZW - UDZ series double color electric contact water level gauge is suitable for all kinds of tajikistan, cans, spherical container and boiler equipment such as medium level measurement.Equipped with limit switches, liquid level can be realized, the lower limit alarm and control;Equipped with liquid level transmitter, liquid level signal can be converted into 4 ~ 20 madc simulate signal, realizing remote detection, indicating, recording, and control, also can direct communication with the computer system.

Four, the main features:

1, use full stainless steel, the product gauge display, alarm switch, far transmission: 4-20 ma and containers within the medium separated from each other, no leakage, no wear and tear.Applies to one, two, three types of containers for flammable, toxic corrosive medium container is absolutely safe and reliable.

2, the product has observed wide vision, visual, clear.Can be red and green light, suitable for application in light and dark places.Night watch more apparent, can be applied to the television monitor used at the same time, the effect is very ideal.

3, the product widely applicable: used for low temperature, medium temperature, high temperature occasion.

4, 4-20 ma, this product can output load negative force: more than 250 Ω, transmit PC, PLC automatic control and regulation.At the same time can also be allocated to the alarm switch, the realization of chain protection.

Five, the technical parameters:

1. Nominal pressure (MPa) : 0.5, 1.0, 1.5, 2.0, 2.5, 3.5, 4.5, 5.5, 6.5, 9.5, 16.5 MPa.

2. The medium temperature: - 45 ℃ to 380 ℃.

3. Medium density: acuity 0.45 g/cm3.

4. The flange is made of stainless steel.

5. The process connection: a variety of sizes and grades of convex and concave and convex surface, groove surface of the flange.

6. The flange installation center distance: general type (450-6000 mm), greater than 6000 mm can be consulted.

7. Display range: center distance between the flange.

8. Ontology material: 304, 316, 304 PP, lined with ptfe.

9. According to state: red, green liquid.

10. The power supply voltage: AC36V or AC220V.

11. Far transmission signal: 4-20 ma, load: 250 Ω.

12. Switch signal: one, two users.

13. Applicable medium: water, steam, acid, alkali, oil, ammonia, benzene, other chemical medium.

Six, installation instructions:

1, the hydraulic pressure meter flange and container seal on the flange clamp connection is good, screw down the bolt.

2, drain flange opening, in the float sensor;Note: the float magnet steel end up, not the horse.

3, under the sensor drain flange, install a DN15 valve, with the original liquid level meter and drain pipe connected.

4, connect the power and input power AC36V insert AC220V power (or diameter), will the level to facilitate observation location.

5, open the valve on the first, and then slowly open the valve, especially on the occasion of high pressure, injection pressure, and slowly make the medium slowly into the sensor, in case of float suddenly compression damage observation, according to the liquid level change from red to green one.

6, sewage, water, observe whether water showed that high and low, alarm is normal, without abnormal phenomenon, can be put into use.

Seven, measuring cylinder and electrode installation and maintenance:

1, the measuring tube must be installed vertically.

2, measuring cylinder and measured container with soda water pipe connected to middle installation meet the container valve pressure, temperature, in order to replace the electrodes.

Must be in 3, electrodes coated with a little oil of graphite in thread, sealed flat place mat copper gaskets, gently squeezing until no leakage, factory electrode has been installed, and the water pressure test.

4, run, measuring cylinder should be regular blowdown, cleaning, prevent electrode fouling, so as to prolong service life, ensure accurate and reliable measurement.

Electrode connected to the secondary instrument, wire and tube wall should keep a certain distance.

Eight,Selection of code:

model | generation | code | instructions | ||

ZW-UDZ- | - | -□ | -□ | -□ | |

Pressure of work | O1S | ≤4.41MPa | |||

Working temperature | 01S | 250 or less℃ | |||

Measuring points | 11 | 11point | |||

use | Q | bubble |

Nine, selection of details:

The product name | model | Rated conditions | According to pick up points | Transmitting range |

Boiler drum water level measuring cylinder | ZW-UDZ-02S-19Q | P=15.68Mpa | 19 | ±300mm |

ZW-UDZ-02S-17Q | 17 | ±250mm | ||

ZW-UDZ-01S-19Q | P=4.41Mpa | 19 | ±300mm | |

ZW-UDZ-01S-17Q | 17 | ±250mm | ||

ZW-UDZ-01S-15Q | 15 | ±200mm | ||

ZW-UDZ-01S-13Q | 13 | ±150mm | ||

ZW-UDZ-01S-11Q | 11 | ±100mm | ||

Measuring cylinder of high pressure heater | ZW-UDZ-02S-17G | P=15.68Mpa | 17 | 0~1000mm |

Deaerator measuring cylinder | ZW-UDZ-01S-17Y | P=4.41Mpa | 17 | 0~1700mm |

Ten order, design guidelines:

1, please users read the instructions before you order, or product introduction.

2, provide the measuring point distribution (table 2) that is outside the scope.

3, indicate the alarm, and protect the output position (set).

4, clear an instrument (sampling tube) working pressure, and communicating pipe size of center distance, which leads to the flange specifications.

5, this instrument can take 4 ~ 20 ma, 1 ~ 5 v, 0 ~ 10 ma dc signal output, the user need when ordering, please indicate.

After-sales service commitment:

Level 1, I companies sell products within twelve months appear quality problem, is responsible for free maintenance.

2, the warranty period, any quality problems such as the products of our company, my company is responsible for free repair or replacement.

3, the warranty period, such as user improper use, damaged products, my company is responsible for the maintenance, charge damage parts cost.

4, after the warranty period appear quality problem, my company is responsible for the maintenance, charge damage parts cost.

5, such as user need to my company site services, to users in the province I company service personnel to reach the site within 12 hours, fujian association of foreign languages and user reach the site within 48 hours.