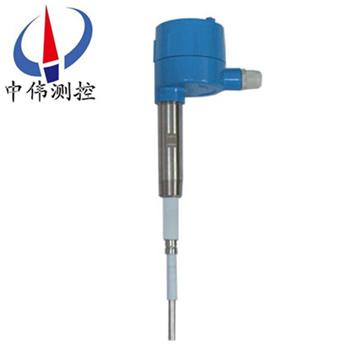

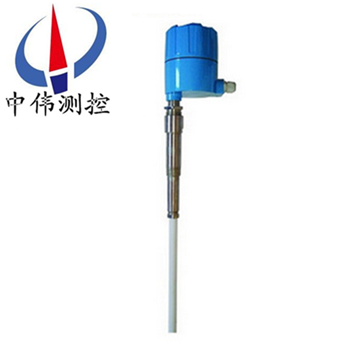

Anti-corrosion type rf admittance level switches

Products overview:

ZW - L2000C seriesAnti-corrosion type rf admittance level switchesIs improved on the basis of original products, improve various properties of the products, and improve the appearance structure, make the product more reliable, beautiful.It adopted the advanced rf admittance technology, overcome the capacitive material level switch cannot eliminate the influence of conductive hanging defects.Reliable operation, the technical instructions are reaching or higher than the international similar products level, are widely used in liquid and slurry, dust, the control of the position.In addition, the product adds to the field work status indication, a very high price performance ratio of high precision level switch.

Second, the working principle:

ZW series - L2000C anti-corrosion type radio frequency admittance level switch consists of a sensor unit and electronic unit.Sensor unit mainly includes three parts: measuring extremely extremely, shielding and grounding terminal, the height of the material reflects for agent and the change of the container wall between admittance, when material arrived in switch, electronic unit to respond, drive the action of the relay, switch signal output.Shaded pole can prevent the misoperation arising from electrode has a hanging signal, only when the material reaches the set point, real output relay on-off signals.

Three, the application object:

ZW - L2000C series anti-corrosion type rf admittance level switches are widely used, several typical situations are as follows: chemical plastic film;Feed/grain rubber drugs;Liquid waste sand;Food mud cement;Powdered coal body paint/coatings;Granular solid oil pulp, etc.

Conductive, insulating liquid:.......................................Chemical, oil field, water and wastewater treatment;

Conductive, insulation slurry:.............................................Paper making, pharmacy, water and wastewater treatment;

Powder: ash, powder:................................................Power plant, metallurgy, cement;

Particles: coal, grain:.............................................Power plant, metallurgy, food;

Interface: different two liquids..............................Oil field, chemical industry.

Four, the main features:

1, strong commonality: measuring liquid level and material level, can satisfy the measurement requirements of different temperature, pressure, medium, and can be applied to negative situations, such as corrosion, impact.

2, prevent hanging: unique circuit design and the sensor structure, can make its measurement is not affected by sensor hanging, without regular cleaning, avoid measurement by mistake.

3, free maintenance: measurement process have no moving parts, no mechanical parts damaged problems, do not need to maintain.

4, anti-interference: non-contact measurement, anti-interference ability is strong, can overcome the steam, foam and mixing effect on the measurement.

Accurate and reliable: measuring amount of diversification, makes the measurement more accurate, measurement is not affected by climate change, high stability, long service life.

Five, the technical parameters:

1, power supply: 220 vac - 50 vac 50/60 hz (standard);

110 vac + 25 vac 50/60 hz (standard).24 vac + / - 5 vac (optional);

2, output: DPDT relay (double pole double throw);

3, the output capacity: 220 vac 5 a;

4, the environment temperature: - 40 ℃ ~ 70 ℃;

5, medium temperature: 100 ℃ ~ 800 ℃;

6, in distinguishing rate: < 0.5 PF;

7, after sex: < 1 mm (conductive medium);< 10 mm (dielectric);

8, response time: < 0.5 s;

9, when delay: 1 ~ 50 s;

10, high and low alarm: the scene can be set up for the HLFS (high alarm way) or produce (low alarm) spark protection (of sensor) : built-in spark protection circuit;

11, electrical interface: M20 * 1.5;

12, the electric cable: split type electronic unit dedicated connections between the sensor and cable standard 5 m, 50 m longest;

13, process connection: the NPT thread installation (standard);Flange installation (optional);

14, shell protection: IP66;

15, explosion proof: Exd iallct4 [1].

Six, installation requirements:

1, radio frequency admittance switch can be installed vertical and horizontal.

2, when installation, must guarantee that the center of the sensor sheath maerial and shielding layer and vessel wall (or installation) each other contact, good insulation, install the threaded connection is firm, with the walls and electrical connection is good, and probe the shield will enter inside the container.

3, with stirring, probe need to support or anchor fixation (fixed end to probe insulation), horizontal instrument service entrance must be down, and the vertical line explosion-proof pipe installation must't bottom line port of mouth, in case of explosion-proof pipe water endanger instrument electronic unit.

4, according to the requirements of explosion-proof instrument installation, wiring of each connected with explosion-proof enclosure must be equipped with a certified seal of stuffing box or explosion-proof steel tube seal joint.

5, certification of seal stuffing box or explosion-proof pipe seal joint product please consult our company and the agent.Instrument installation area requires the lightning protection device, in case of a lightning strike.

6, 24 VDC power supply ripple shall not be greater than 200 mv.

7, power supply ground wire to meet the standard or standard instrument, do not pick up on the floor in power.

Seven, notable matters of installation:

1, the installation location not being too close to the mouth, otherwise, when the material easy to receive fake echo.

3, for the original coal cylindrical, shall be installed in the cylinder radius in half, the sensor should be aimed at discharging port.

3, connection

Level switches required for different voltage grade are different according to the model, in order to ensure the personal safety and equipment in good condition, should be in the case of power wiring.

Connection mode is divided into two wire system and four wire system,

We collected is 4-20 ma current signal, to prevent electromagnetic interference on site, ensure the accuracy of signal, should use shielded cable, shielding grounding cable end.

Eight,Selection of code:

ZW-L2000C | Rf admittance level switchesWei measurement and control of the () | |||||

The power supply | ||||||

A | 220VAC | |||||

B | 24VAC | |||||

C | 110VAC | |||||

Time delay | ||||||

D | There is no | |||||

E | 0-50s | |||||

The sensitivity | ||||||

F | standard | |||||

C | Small scale high sensitivity | |||||

The sensor | See the sensor selection table | |||||

I | The whole installation | |||||

R | Fission installation | |||||

explosion-proof | ||||||

E | There are | |||||

Z | There is no | |||||

Nine, sensor selection table:

electrode Serial number | Electrode form and typical applications | Working temperature and working pressure | The length of the | Electrode diameter and material | Install the connection form |

02 | standard Light is used in the liquid, slurry, particle density p (240 kg/m3) | 121℃/1.38MPa | 457mm(18") | 9.5 mm / 316 ss and PTFE | 3/4"NPT |

07 | High temperature type Light is used in the liquid, slurry, particle density p (240 kg/m3) | 232℃/1.38MPa | 457mm(18") | 9.5 mm / 316 ss and T1 | 3/4"NPT |

22 | Heavy hanging standard Used for light mixing liquid and slurry, particles (or greater density 240 kg/m3) | 149℃/3.45MPa 232℃/1.38MPa | 457mm(18")/ 914mm(36") | 12.7 mm / 316 ss and TFE | 1"NPT |

55 | The corrosion type Light used for liquid, slurry, particle density p (240 kg/m3) | 232℃/1.38MPa | 457mm(18")/ 914mm(36") | 9.5 mm / 316 ss and T1 | 3/4"NPT |

20 | Flat probe For chute, hopper blockage detection, low material level | 149℃/0.007MP | 304.8 * 304.8 mm (12 * 12 ") / 304 ss and polyurethane | built-in | |

30 | Flexible probe Used for high/low level insert > length of 15 m | 82 ℃ atmospheric | 15m | 4.7 mm / 304 ss and rubber | 1"NPT |

Note: 1, PTFE teflon;More than 2, as the standard length, according to the users can switch the length of the production.

Ten, design selection and ordering information:

1, liquid level control device specifications;

2, measurement range;

3, working pressure, and temperature;

4, control device for material;

5, special requirements;

6, whether level device matching supply vessel flange, bolts, nuts, valves and fittings such as sealing washer, so that the correct selection.

After-sales service commitment:

1, my company the liquid level switch series of products are sold within 12 months appear quality problem, is responsible for free maintenance.

2, the warranty period, any quality problems such as the products of our company, my company is responsible for free repair or replacement.

3, the warranty period, such as user improper use, damaged products, my company is responsible for the maintenance, charge damage parts cost.

4, after the warranty period appear quality problem, my company is responsible for the maintenance, charge damage parts cost.

5, such as user need to my company site services, to users in the province I company service personnel to reach the site within 12 hours, fujian association of foreign languages and user reach the site within 48 hours.