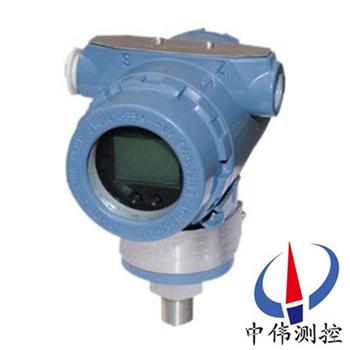

Intelligent pressure/pressure transmitter

ZW3851AP seriesIntelligent pressure/pressure transmitterIs the application of digital technology, in addition to ensure that the instrument of high reliability and superior performance, the other can realize real time self-check configuration and operation of intelligent instruments and digital remote connection between the control room, control room of unit instrument remote query or real-time configuration.High precision and good stability.Adjustable range, zero outside.Miniaturization, light weight, strong resistance to vibration.No mechanical moving parts, reliable operation, easy maintenance.Connect the solid element, printing circuit board.Explosion-proof structure, can be all-weather use.

Second, the working principle:

ZW3851AP series intelligent absolute pressure/pressure transmitter is when two of the measured medium pressure ventilation with high and low pressure chamber, two effects at both sides of the components (i.e., sensitive element) on isolated patch, through spacer and components on both sides of the filling liquid to measure the diaphragm.Measuring diaphragm and on both sides of the insulation on the electrodes of a capacitor.When we have different pressure on both sides, to cause measuring diaphragm displacement, the displacement and stress is directly proportional to the difference, so both sides capacitance range, through the link of oscillation and demodulation, is converted into is proportional to the pressure signal.And the principle of absolute and differential pressure transmitter is the same, the difference is low pressure chamber pressure is atmospheric pressure or vacuum.

Applications:

ZW3851AP series intelligent absolute pressure/pressure transmitter can be realized on the degassing system, distillation tower, the absolute pressure inside the evaporator and mold equipment such as measuring, allowed under 10 mpa pressure.Absolute pressure transmitter of the delta chamber side accept absolute pressure signal being measured, the benchmark closed at the other side into a high vacuum chamber, and then convert them into 4 ~ 20 ma DC signal output.

Four, the main features:

1, the super performance measurement for pressure, differential pressure, liquid level, flow measurement;

2, digital precision: + (-) 0.05%;

3, stability: 0.25% 60 months;

4, range: 100:1;

5, measuring rate: 0.2 S;

6, miniaturization (2.4 kg) stainless steel flange, easy to install;

7, process connection compatible with other products, the realization of measurement;

8, the world's only USES the H alloy sheath of sensors (technology), achieved good cold and hot stability;

9, 16 computer;

10, standard 4-20 ma, with digital signal based on HART protocol, the remote control support to field bus and upgrade based on the technology of field control.

ZW3851AP | (In the wei and control) | ||||||||

4 | 0 to 6~40KPa | ||||||||

5 | 0 to 40~200KPa | ||||||||

6 | 0-0.16~1MPa | ||||||||

7 | 0-0.4~2.5MPa | ||||||||

8 | 0-1.6~10MPa | ||||||||

Code name | function | ||||||||

N | General simulation model (output: 4 ~ 20 ma) | ||||||||

G | Conventional intelligence (output: 4 ~ 20 ma) | ||||||||

S | Standard smart (output: 4 ~ 20 ma with HART bus protocol) | ||||||||

Code name | Junction structure materials | ||||||||

Flange joint | Vent/drain valve | Isolation diaphragm | Pump the liquid | ||||||

22 | 316Stainless steel | 316Stainless steel | 316Stainless steel | Silicone oil | |||||

23 | 316Stainless steel | 316Stainless steel | Hartz C - 276 | ||||||

24 | 316Stainless steel | 316Stainless steel | monel | ||||||

25 | 316Stainless steel | 316Stainless steel | tantalum | ||||||

Code name | precision | ||||||||

Q1 | 0.2%FS | ||||||||

Q2 | 0.5%FS | ||||||||

Code name | Electrical connection in the head | ||||||||

L1 | M20X1.5Internal thread | ||||||||

L2 | 1/2NPTInternal thread | ||||||||

Code name | Additional options | ||||||||

M1 | 0~ 100% linear instructions header | ||||||||

M3 | Digital display meter | ||||||||

B1 | 2"Pipe bracket with bending | ||||||||

B2 | Bracket with curved wall/board | ||||||||

B3 | 2"Pipe bracket with flat | ||||||||

D0 | Relief valve in central pressure chamber | ||||||||

D1 | The upper side discharge valve in the pressure chamber | ||||||||

D2 | Lateral release valve at the bottom of the pressure chamber | ||||||||

C0 | 1/2"The cone tube nipple | ||||||||

C1 | 1/2"Lead pressure joints and the back of the welding pipe phi 14 (supply including C0) | ||||||||

C2 | Jump nipple M20X1. 5 | ||||||||

d | Flameproof EXd Ⅱ CT5 | ||||||||

i | The Ann model EXia Ⅱ CT6 | ||||||||