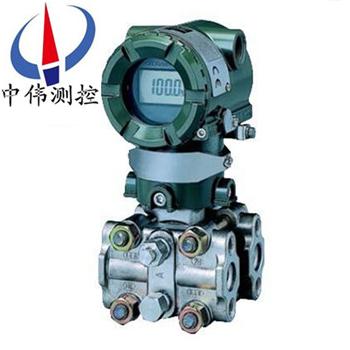

Monocrystalline Silicon Pressure Transmitter

I. Product Overview:

ZWA430A series single crystal silicon pressure transmitter consists of intelligent sensor and smart electronic board. The smart sensor includes capacitive sensor, diaphragm detection circuit, temperature sensor and temperature compensation circuit. The smart electronic board includes microcontroller and peripheral circuit to complete the conversion of pressure signal to 4-20 mA dc. It is used to measure the pressure of liquid, gas or steam, and then convert the pressure signal into 4-20 mA DC signal output.

2. The influence of static pressure is neglected.

ZWA430A series single crystal silicon pressure transmitter with static pressure (working pressure), the two resonant beams with identical shape, size and material have the same deformation, so the frequency change is the same, so the deviation is automatically eliminated (formula and figure are similar to temperature effect).

3. Excellent unidirectional overvoltage characteristics:

ZWA430A series liquid-contacting diaphragm and diaphragm body adopt original ripple processing technology. When the external pressure increases to a certain value, the liquid-contacting diaphragm can fully contact the body, and the pressure transmitted by silicone oil to the sensor does not increase with the increase of the external force, so as to achieve the protection of the sensor.

4. Application occasions:

ZWA430A series single crystal silicon pressure transmitter is used to measure the flow, liquid level, density and pressure of gas, liquid and steam, and then convert it into current signal output of 4-20 mADC. ZWA430A can also communicate with each other through BRAIN or CENTUM CS/uXL or HART275, through which they can be set up and monitored.

V. Main characteristics:

1. Super measurement performance for pressure, differential pressure, liquid level and flow measurement;

2. Digital accuracy: +(-) 0.2%;

3. Stability: 0.25% for 60 months;

4. Range ratio: 100:1;

5. Measurement rate: 0.2S;

6. Miniaturized (2.4kg) stainless steel flange, easy to install;

7. Process connection is compatible with other products to realize measurement.

8. The only sensor in the world that uses H-alloy sheath (technology) achieves excellent cold and thermal stability.

9. Intelligent transmitter with 16-bit computer;

10. Standard 4-20mA, with HART-based digital signal, remote control supports upgrading to fieldbus and field control technology.

6. Technical parameters:

1. Targets: liquids, gases and vapors;

2. Measurement range: 0-0.08kPa to 0-40 MPa;

3. Output signal: 4-20mA DC (special for four-wire system); 220V AC power supply, 0-10mA DC output;

4. Power supply: 12-45V DC, generally 24V DC;

5. Load characteristics: related to power supply, with load capacity at a certain power supply voltage; the relationship between load impedance RL and power supply voltage Vs is: RL < 50 (Vs-12);

6. Indicator table: pointer linear indicator 0-100% calibration and LCD liquid crystal display;

7. Explosion-proof grade: a: Exd II BT5 or Exd II CT6; b: intrinsically safe type (Exia II CT6 or Ex IB II CT6);

8. Range and Zero: External continuous adjustable;

9. Positive and negative migration: The absolute values of range, upper limit and lower limit of measurement range can not exceed 100% of the upper limit of measurement range after positive or negative migration of zero. The positive and negative migration of Zui is 500% of the calibration range of Zui minor adjustment, and the negative migration of Zui is 600% of the calibration range of Zui minor adjustment.

10. Temperature Range: Working Temperature Range: - 20 ~+88 C.

7. Installation requirements and precautions: