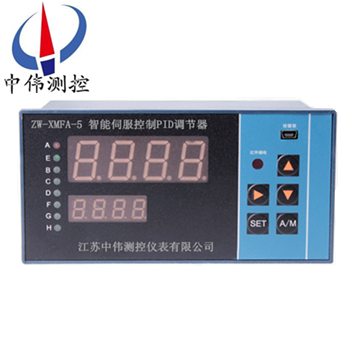

Intelligent servo control PID regulator

Products overview:

ZW - XMFA seriesIntelligent servo control PID regulatorWith its simple structure, good stability, reliable operation, easy to adjust and become one of the main technology of industrial control.When the structure and parameters of the controlled object is not fully grasp, or not precise mathematical model, the control theory of other technology is difficult to use, the structure and parameters of system controller must depend on experience and on-site commissioning to determine, then the application of PID control technology is convenient.When we don't fully understand a system and controlled object, or not through effective measurements to obtain the system parameters, suitable for PID control technology.PID control, the practice also have PI and PD control.PID controller is based on the error of the system, the use of proportion, integral, differential calculate the control quantity control.

ZW - XMFA series intelligent servo control PID regulator collected at present most of the functions of automatic control system of regulating various instruments, but also integrates the CPU, I/O interface, such as EPROM and D/A conversion circuit, supplemented by being open, elaborate, debugging software system allows you to repeatedly in the process of production with ease, such as wing arm.And the product is not the past simple sense of the survey instrument, in operation, such as comparison, execution, alarm processing ability has a satisfactory performance.

Second, the applications:

ZW - XMFA series intelligent servo control PID regulator is used for small and medium-sized technology device of temperature, pressure and other parameters of the single loop control.Can be applied to metallurgy, petroleum, chemical industry, building materials, paper making, food, medicine, heat treatment and water treatment and other industrial field.

Second, the main functions:

1, all kinds of analog input or frequency.

2, process capacity, given value, the control quantity, quantity of valve position feedback, such as multiple display.

3, the measured value with the given value addition and subtraction can be performed.

4, choice of servo control PID regulator of positive and negative effects

5 can be set respectively, control limit and lower limit the output control.

6, calibration of analog quantity of valve position feedback can be zero and full.

7, 2, or 3 analog output is: 0 ~ 10 ma, 4 ~ 20 ma.

Eight, eight kinds of alarm control mode selection.

9, with functions of motor and reversing control of braking.Valve position feedback failure can relay output.

10 the given value, input switch SB function control transfer.

11, built-in 41 a bidirectional thyristor direct control of the electric actuator.

12, measure the input signal prescribing and small signal can be removed.

13 and boot boot manually or automatically position to keep or boot manual presets.Valve position feedback automatic break into manual (need) indicate the order

14, can be realized with intelligent sound and light alarm, intelligent sound attenuation time timer or counter function.

15, the PID parameters self-tuning or P parameters self-tuning independently.The 8 groups of set value and the PID parameters storage and call.

16, remote automatic state control.The remote work station an able person;Remote control switch quantity control regulator output for PID regulating mode or work station an able person operating state, two-way undisturbed switching;Remote control servo PID regulator controls or PC directly.

17, PC directly control input signal failure when transferred to own the PID control mode;PC directly control mode;Servo control PID regulator automatically tracks the input signal of the upper machine.

18, can provide multiple host, single host, host form of asynchronous serial communication interface RS485.Communication data validation in accordance with CRC - 19, the data communication standards, high reliability circulation, bar code check.

Four, commonly used formula:

1, the commonly used PID formula:

Parameter setting to find ideal, from small to large, check the order

First the proportion integral, zui and then add the differential,

Curve of oscillation is very frequent, proportional scale to enlarge,

Curve floating around the big bay, proportion dial to the small pull,

To decline curve deviation reply slow, integral time,

Curve fluctuation cycle long, the integral time to lengthen,

Curve of oscillation frequency is fast, to cut down the differential,

Dynamic differential big fluctuations to slow, differential time should be longer,

Two wave ideal curve, after the high low before 4 to 1.

2, a look at two more analysis:

3, principle and features:

Widely used in engineering practice, the regulator control law for the proportion, integral and differential control, hereinafter referred to as PID control, also known as PID regulation.

Regulating quality will not low 2. Engineering parameters for PID controller, P.I.D parameters in various regulating system experience data can refer to the following: the temperature T: P = 20 ~ 60%, T = 180 ~ 600 s, D = 3 P - 180 - s pressure: 30 ~ 70%, P = T = 24 ~ 180 s, liquid level L: P = 20 ~ 80%, T = 60 ~ 300 s, flow L: 40 ~ 100%, P = T = 6 ~ 60 s.

Five, instrument installation:

1. The instrument installation

1.1 meter before installation should check instrument model, index number, measurement range and sensor.

1.2 meter horizontal and vertical two types respectively, and the horizontal type torque type, horizontal type square and upright rectangle and several vertical square, etc.

2. The hole size

2.1 type 152 x 76 mm (a)

2.2 vertical 76 x 152 mm (b)

92 x 92 mm (c) 2.3 square

Six, selection table:

| ZW-XMPA | —— | Said Ming | ||

| Design sequence | 5 | Wei measurement and control in intelligent servo control PID regulator () | ||

| Display mode | 1 | Double screen | ||

| 2 | Three screen display | |||

| 3 | Double screen + single beam | |||

| 4 | Double screen + double beams | |||

| 5 | Single + double beams | |||

| 6 | Single + three beams | |||

| Input mode | 1 | With a thermocouple (E, K, S, B, J, T, R, N) | ||

| 2 | With thermal resistance (Pt100, Cu50, Cu100, BA1, BA2, G) | |||

| 3 | With direct current (0 ~ 10 ma, 4 ~ 20 ma) | |||

| 4 | With a dc voltage (0 ~ 5 v, 1 ~ 5 v, 0 to 20 ma, 0 ~ 75 ma, 0 ~ 200 ma), | |||

| 5 | With remote transmission pressure resistance and linear resistance value (0 ~ 400 Ω) | |||

| 6 | All with 1 ~ 5 types, user can change at any time including any kind of input type | |||

| 7 | Frequency input (0 ~ 10 KHZ) | |||

| 8 | Special input (such as root, cut of small signal, order please indicate) | |||

| Control the output and the adjustment way | The continuous PID way | 1 | PID4 ~ 20 ma output (reaction) | |

| 2 | PID0 ~ 10 ma output (reaction) | |||

| 3 | PID0 ~ 5 v output (reaction) | |||

| 4 | PID1 ~ 5 v output (reaction) | |||

| 5 | PID0 ~ 10 v output (reaction) | |||

| 6 | One positive effect (1 ~ 5, order indicate) | |||

| 7 | One 1 ~ 6 + relay indicating the amount and type of relay (order) | |||

| Intermittent PID way | 1 | Built-in SCR (two-way within 41 a, 2 kw) output | ||

| 2 | Built-in SCR (two-way 41 a, 2 kw) output (add 2 or 3 relay, order indicate) | |||

| 3 | External SCR silicon silicon (single or double) | |||

| 4 | Silicon silicon thyristor converter (single or double) (add 2 or 3 relay, order indicate) | |||

| 5 | Three phase zero interpolation method is used thyristor trigger (trigger current more than 500 ma) | |||

| 6 | Three-phase thyristor zero trigger add 1 or 2 relay (order) indicated | |||

| 7 | SSR solid state relay output (12 v) plus two relay alarm (users with SSR technology parameters) | |||

| Additional features (note) | 0 | No additional features | ||

| 1 | Output limit, lower limit control | |||

| 2 | There are boot manual function | |||

| 3 | EM1 function | |||

| 4 | EM2 function | |||

| 5 | SB function | |||

| 6 | Self-tuning function | |||

| 7 | 8 groups of PID parameter selection | |||

| 8 | The ratio control: SP = x outside A given + B | |||

| 9 | Display and valve position feedback tracking control (the default input 4-20 ma) or order | |||

| Overall dimensions | H | Horizontal type 160 x 80 | Opening 152 x 76 | |

| V | Vertical 80 x 160 | Opening 76 x 152 | ||

| F | The way to 96 by 96 | Opening 92 x 92 | ||

| Q | The way to 72 by 72 | Opening 68 x 68 | ||

| Analog output | A | There is no analog output | ||

| B | Analog 0 ~ 10 ma | |||

| C | Analog output 4 ~ 20 ma | |||

| D | Analog 0 ~ 5 v | |||

| E | Analog output 1 ~ 5 v | |||

| F | Special signal analog output | |||

| G | Feedback the output (the default input) | |||

| Timing function | S | Default is no timing function | ||

| With the function of timing | ||||

| For the 24 v dc power supply | P | Default is no 24 v dc power supply output | ||

| With 24 v dc output power (to do two wire transducer power) | ||||

| Communication interface | T | The default is not to bring a communication interface | ||

| With RS485 and RS232 communication interface | ||||

| Power supply | K W | Default is 220 v AC | ||

| Switching power supply of 85 ~ 260 vac | ||||

| Switching power supply 18 to 36 VDC or 18 ~ 36 vac | ||||

After-sales service commitment:

1, our company sold by wei measurement and control products quality problems within twelve months, responsible for free maintenance.

2, the warranty period, any quality problems such as the products of our company, my company is responsible for free repair or replacement.

3, the warranty period, such as user improper use, damaged products, my company is responsible for the maintenance, charge damage parts cost.

4, after the warranty period appear quality problem, my company is responsible for the maintenance, charge damage parts cost.

5, such as user need to my company site services, to users in the province I company service personnel to reach the site within 12 hours, fujian association of foreign languages and user reach the site within 48 hours.